- Review articles

- Open access

- Published:

Methods for Detection of Subsurface Damage: A Review

Chinese Journal of Mechanical Engineering volume 31, Article number: 41 (2018)

Abstract

Subsurface damage is easily induced in machining of hard and brittle materials because of their particular mechanical and physical properties. It is detrimental to the strength, performance and lifetime of a machined part. To manufacture a high quality part, it is necessary to detect and remove the machining induced subsurface damage by the subsequent processes. However, subsurface damage is often covered with a smearing layer generated in a machining process, it is rather difficult to directly observe and detect by optical microscopy. An efficient detection of subsurface damage directly leads to quality improvement and time saving for machining of hard and brittle materials. This paper presents a review of the methods for detection of subsurface damage, both destructive and non-destructive. Although more reliable, destructive methods are typically time-consuming and confined to local damage information. Non-destructive methods usually suffer from uncertainty factors, but may provide global information on subsurface damage distribution. These methods are promising because they can provide a capacity of rapid scan and detection of subsurface damage in spatial distribution.

1 Introduction

Hard and brittle materials are widely used because of their excellent physical and mechanical properties, such as high hardness and strength at elevated temperatures, wear and corrosion resistances, etc. Among hard and brittle materials, single crystalline silicon is the predominant substrate material for integrated circuits (IC) [1,2,3,4,5]; optical glasses are for optical windows and lens [6,7,8,9,10,11] as well as high-power laser components [12]; ceramic materials are commonly used for bearings, cutting tools and machine parts [13,14,15,16]. However, these materials are also difficult to machine due to their hard and brittle nature. Surface and subsurface damage (SSD) is often induced in a machined part made of such a material.

Due to the ever-increasing requirement for better surface integrity of mechanical and optical parts, the tolerance for surface and subsurface damage is getting tighter and tighter. It becomes necessary to detect and remove surface and subsurface damage in a machining process. Damage detection is thus important to manufacturing of hard and brittle materials. It does not only provide information on size, type, location and spatial distribution of surface and subsurface damage, but also gives a guideline for the subsequent machining processes to remove damage so as to improve efficiency and quality, and reduce cost for the manufacturing processes.

While surface damage is relatively easy to detect because many existing techniques, such as optical scanning, are available to use, subsurface damage is rather hard to detect since such a damage is often hidden in the subsurface at a certain depth. There are many types of subsurface damage, such as cracks, residual stress, porosities, phase transformation, amorphization, among which cracks are most detrimental and directly determine performance and lifetime of a part. Both destructive and non-destructive methods have also been developed for subsurface damage detections. Destructive methods include taper-polishing, cross-sectional microscopy, and etching, whereas non-destructive methods are X-ray scanning, laser scattering, and ultrasonic probing, etc. In comparison with the non-destructive methods, the destructive methods have better reliability and accuracy. However, the destructive methods need to destroy the part, do not provide global damage information of the part, and are time-consuming in sample preparation. On the other hand, non-destructive methods can realize in-process detection without the above drawbacks, and may greatly reduce cost, and improve efficiency and quality for machining. The major problem associated with the non-destructive methods is the detection accuracy and efficiency which need to be improved.

This paper provides a review of the methods for detection of subsurface damage. It discusses mechanisms of subsurface damage formation, and methods for subsurface damage detection. The paper also outlines the recent developments in subsurface damage detection. The paper compares the methods and techniques for the improvement of detection accuracy and efficiency, and further points out limitations and drawbacks of the methods and techniques.

2 Mechanisms of Subsurface Damage Formation

Zhang et al. [14, 17, 18] assessed subsurface damage induced by single diamond scratching of different ceramics and observed that subsurface damage included median (radial) and lateral cracks, as well as pulverization zone, as shown in Figure 1. During the scratching process, the pulverized material is squeezed to the two sides of the groove to form material pile-up. Under the influence of the loading stress, the region underneath the abrasive grain was turned into a pulverization zone as a consequence of pulverization and collapse of the internal pores in the material. The pulverization zone was surrounded by a zone of elastic-plastic deformation. During scratching, a median crack could be initiated at the point where the stress level exceeded the tensile strength of the material. When the abrasive grain moves away, the median crack is closed due to the elastic springback. Meanwhile, the elastic-plastic deformation zone begins to restore, lateral cracks are formed and tends to propagate to the surface. Friction between the abrasive grain and surface of the workpiece elevates the temperature in the machining area. Because the material grains in the pulverization zone are fine enough, they can be re-sintered so as to form a smearing layer that covers the scratching pass. Some lateral cracks may propagate and intersect each other and result in material removal. The residual cracks form subsurface damage.

Schematics of subsurface damage induced in a scratching process [18]

Subsurface damage is detrimental to the strength, lifetime and performance of a part, and is necessary to be removed in subsequent processes. To detect SSD is critical to the correct adoption of the subsequent processes. Methods for detecting SSD in a part made of a hard and brittle material are classified into two categories: destructive and non-destructive. Destructive methods include tapper polishing, SEM microscopy, TEM microscopy, cross-sectional microscopy and chemical etching. On the other hand, non-destructive methods are mainly optical coherent tomography and laser scattering, etc. These methods are compared and discussed in detail in the following three sections.

3 Destructive Methods

In the application of destructive methods for SSD detection, a machined part has to be destroyed in order to expose and detect SSD. Destructive methods are relatively mature with acceptable detection accuracies. They are widely used in academia and industry.

3.1 Polishing Techniques

3.1.1 Traditional Taper Polishing

The traditional taper polishing is one of the widely used methods for subsurface damage detection and observations [1, 2, 19,20,21,22,23,24,25,26]. Figure 2 shows the schematics of the taper polishing method. A machined sample is cut at an angle β to the machined surface and then the cut surface of the sample is polished to remove possible damage induced by the cutting process. The polished sample is etched to remove the smearing layer of the polished surface and thus SSD is exposed in the sample. The SSD is then observed with a microscope and measured for damage dimensions. The depth H of SSD is calculated as in Eq. (1):

Schematics of the traditional taper polishing method [1]

Similar to the other traditional methods, the taper polishing method is direct, accurate, inexpensive, and easy to operate with satisfactory measurement results. However, it is a destructive method, and thus cutting and polishing the sample may introduce new damage to the sample, which adds errors to the measurement results. In addition, applying etching to a polished sample inevitably releases the strain energy at a crack tip, and extends the crack length. In this regard, the taper polishing method typically measures a crack with an extended length [27].

3.1.2 Dimpling

A novel method, named “ball dimpling”, has been used to detect subsurface damage in machining of optical parts. The method was developed by the Optical Manufacturing Center of the University of Rochester [28, 29]. Similar to the traditional taper polishing method, the ball dimpling method polishes a sample part with a steel ball to make a dimple in order to expose the subsurface damage of the part. The depth of the dimple is large enough so as to cross the damage layer to the matrix. The depth of SSD is calculated by measuring the characteristic dimensions of the dimple. There are also some other forms of dimpling [30]. The ball dimpling method is simple in operation and low in cost. However, the scratches in a dimpling process may remain on the part surface, which can result in measurement errors. Additionally, the ball dimpling method is time consuming in SSD measurements for the parts made of hard materials due to a low dimpling efficiency [31].

3.1.3 MRF Polishing

With the development of precision machining technology, the magnetorheological finishing (MRF) polishing is used in the SSD measurements [11, 19, 31,32,33,34,35]. It has been reported that the shear effect plays an essential role in material removal with the MRF polishing, which ensures no extra damage introduced into the workpiece [28, 36,37,38]. The MRF polishing technology is to create a spot or a wedge on the surface of a part. The spot or the wedge crosses the damage layer to the damage-free matrix. The depth of SSD can be inferred by measuring the width of the spot or the wedge. The depth of SSD is usually tens of microns but the width of the spot is in the order of millimeters. The depth of damage is magnified hundreds of times in this way, which improves the accuracy of the measurement.

Only the local SSD information is detected with either the taper polishing or the MRF polishing method, the global information and spatial distribution of SSD are not provided. A sample has to be etched before observation with a microscope. The size and the distribution of SSD cannot be correctly assessed if a polished sample is over etched. Since sample etching is highly depended on the type and concentration of an etchant, the temperature and the etching time, it is rather difficult to precisely control an etching process. In addition, a subsurface damage may be overly measured because an etching process can release the energy at the crack tip so as to extend crack length.

3.2 Bonded-Interface Technique

The bonded-interface technique (BIT) was first proposed by Mulhearn et al. [39] to investigate the material deformation of metals in an indentation test. Figure 3 shows the schematics of BIT that is divided into multiple steps. Firstly polish the surfaces which need to be bonded together; secondly bond the polished surfaces, and machine the work surface; then remove the bonding glue, and observe SSD on the two polished interfaces with a microscope. BIT has a limited application to measuring subsurface damage in the parts made of ceramics, optical glasses and other hard and brittle materials by researchers [40,41,42,43,44] due to its false representation in the resulted stress-strain fields [45].

Schematics of bonded-interface technique [40]

One critical problem with this technique is that the sample has a bond layer, which changes the stress-strain fields nearby the interface when the sample is subjected to indentation at the interface. The Hertzian theory can no longer be applied to analyzing the stress-strain field in this case. Helbawi et al. [45] found that the maximum stress position shifted away from the bonded-interfaces in both finite element simulation and indentation experiments. In consequence, the maximum subsurface damage depth was away from the bonded-interfaces and was larger than the measured damage depth. However, the damage zone observed with BIT was with a higher damage density than that induced in the practical machining processes. The findings from Helbawi et al. [45] verified the limitation in BIT. Therefore, BIT cannot provide precise information on subsurface damage induced in the practical machining processes, and should not thus be recommended for quantitative detection of SSD in hard and brittle materials.

3.3 Cross-sectional Microscopy

Due to the amorphous layer induced in a machining process, it is not convincing to observe SSD from a machined surface. An additional cross-sectional inspection gives more precise information on SSD. Carr et al. [46] observed SSD of optical glasses from the cross section of a fracture part with a scanning electron microscope. Zhang et al. [14] presented a method to prepare a fractured cross section and procedures to observe SSD. However, in their method, a sample has to be split up. In addition, only the SSD in the fractured surface can be observed and measured, but their overall distribution and three-dimensional configurations remain unknown.

3.4 Transmission Electron Microscopy

The transmission electron microscopy (TEM) has been used to observe micro damage in a sample at a high resolution [47,48,49]. Subsurface microcracks, dislocation, amorphous and polycrystalline layers and other micro and nano defects can precisely be observed with TEM. The sample is often observed from both the horizontal and cross-sectional views to give a more comprehensive estimation on SSD. Although it provides more precise information, TEM requires the sample to be thin enough due to the high scattering on and poor penetration into the surface of the sample by electrons. Generally, a sample is first thinned to 20‒50 μm, and then further to less than 1 μm by ion milling [2, 21, 49]. Therefore, the preparation procedure is complicated and time-consuming.

3.5 Chemical Etching

Chemical etching is to use a suitable etchant to remove the damage layer of a machined sample. The surface morphology and roughness after etching, as well as etching rate are used to evaluate subsurface damage. There are different inspection methods for estimating SSD using chemical etching.

One method is based on the surface roughness of an etched sample [12, 35]. Wong et al. [50] measured the peak-to-valley (PV) value and root-mean-square deviation R q of the surface profile with a detection probe at each etching stage. At the initial etching stages, a crack is exposed, which allows the tip of the probe to reach the inside of the crack, thus resulting in a high measurement value of surface roughness. With an increase in etching time, more and more cracks are exposed and intersect with each other to result in material removal. The number of subsurface cracks decreases after each etching stage, which leads to a decrease in surface roughness. The removal of the damage layer stabilizes surface roughness, which facilitates an accurate calculation of SSD depth.

There are constant- and differential-rate inspection methods based on etching rate. The constant-rate etching method controls the influence factors as constants, such as temperature, etchant concentration, and time. A sample is etched step by step, and etching rates are recorded at every step. Since damage introduces more contact surfaces with the etchant, the contact area between the etchant and the surface layer decreases as the damage layer is removed step by step. Therefore, etching rate is decreased correspondingly, shown in Figure 4. After the damage layer is removed, etching rate is stabilized, and SSD depth can thus be calculated according to the etching rate graph in Figure 4.

Etching rate vs. etching time for the silicon wafers ground by #2,000 diamond wheel [2]

The constant-rate etching method has been widely used to measure SSD in optical glasses, ceramics, and semiconductor materials [2, 22, 50,51,52]. The method records the absolute etching rate. However, the etching process is affected by many factors, such as etching time, etchant concentration, and temperature. It is difficult to simultaneously control all the influence factors.

In order to eliminate the influence of these factors and improve the measurement accuracy, Wang and Li et al. [19, 53, 54] proposed the differential-rate etching method. The method was to etch the machined and damage-free samples in the same environment simultaneously, and then to compute the differential-rate. SSD depth can be calculated based on the differential-rate.

As argued before, chemical etching promotes crack propagation, which results in larger measurement values of SSD compared to the actual ones. It has low repeatability and measurement efficiency. In addition, most etchant is poisonous, which is highly detrimental to human health and environmental protection.

The destructive methods for SSD are relatively reliable. However, there are still many disadvantages to be overcome in the future. A comparison of the destructive methods is presented in Table 1.

4 Non-destructive Methods

The destructive methods are time-consuming, which reduces production efficiency and increases cost. Non-destructive methods preserve the samples and detect SSD based on the knowledge of optics and acoustics, etc. In this section, four non-destructive methods are presented and discussed.

4.1 Predictive Methods

The predictive methods are mainly to predict SSD depth. There are two types of prediction based on process parameters and surface roughness (SR) of a machined part.

SSD depth can be empirically predicted with the size of abrasive grains during grinding or lapping, for which several researchers arrived at different results [40, 55,56,57,58]. Lambropoulos et al. [59] proposed a relationship between the damage depth and the size of abrasive grains, expressed as Eq. (2),

where d is abrasive grain size and δ is SSD depth.

Zhang et al. [17] built a predictive model based on material properties and grinding parameters to predict the depth of subsurface damage δ of ceramics induced in grinding, expressed as Eq. (3),

where a g is the maximum cutting depth of abrasive grains, taking the form shown in Eq. (4); λ is constant, and λ=10−2m1/2; m is the working condition coefficient, and 1/2<m<2/3; H and K c are the hardness and the toughness of a workpiece material, respectively.

where v w is the feed of a workpiece, v s is the peripheral speed of a grinding wheel, r is the ratio of the width to the thickness of the non-deformed chips, a p is the cutting depth of abrasive grains, d s is the diameter of the wheel, and C is the grain density on the wheel surface.

The other predictive method uses the surface roughness information of a machined part for SSD depth prediction. The method is derived from fracture mechanics that is used to study cracking behavior. In studying lapping of glasses and ceramics with SiC abrasives, Aleinikov et al. [60] reported that the ratio of surface roughness and SSD depth was 3.9 ± 0.2. However, the ratio was different due to different workpiece materials, machining processes and SSD measurement methods [31,32,33, 40, 58, 61, 62].

Based on the indentation fracture mechanics, Lambropoulos et al. [61] considered that the formation of SSD was due to the brittle fracture of a workpiece material, and proposed an explicit equation to predict SSD depth, as shown in Eq. (5),

where E, H, and K c are the elastic modulus, the hardness, and the toughness of the workpiece material, respectively. ψ is the semi-angle of the sharp cone of an abrasive grain; P is the force acting on the grain. \(\alpha_{\text{K}}\) and m are numerical factors in ranges of 0.03–0.04 and 0.33–0.50, respectively. Force P determines the ratio, yet in practical machining, it varies with process parameters, which renders the model inconvenient to use.

Li et al. [11, 19] improved the model in Eq. (5), stated that the relationship between SSD and R a should be non-linear, as expressed in Eq. (6). Damage depth is directly related to surface roughness by eliminating grain force P,

Lv et al. [9] built a model to predict damage in a BK7 glass sample machined by the rotation-ultrasonic machining and grinding. In their study, damage depth was found to be proportional to the second order function of surface roughness, namely, \(\delta = \chi SR^{2} + l\), where constant l is related to the geometric shape of abrasives and to material properties. The constants in the model were derived from the experimental data fitting.

It is necessary to point out that these models reveal the relationship between SSD depth and surface roughness in terms of indentation fracture mechanics. Indentation is a quasi-static interaction between the tool and the workpiece. They ignored the effect of cutting speed on machining-induced damage. Li et al. [6] studied the effect of grinding wheel speed and workpiece feed rate on SSD of the BK7 glass, shown in Eq. (7),

where λ is related to the material properties of the workpiece and the geometric shape of the grains; v w is the workpiece velocity; L is the spacing between the successive cutting edges; v s , a, and are the speed, the depth of cut, and the diameter of the wheel. However, this model assumed a constant grit protrusion height, which does not conform to the practical grinding process.

Chen et al. [8] studied the influence of the wheel vibrations on SSD depth. They built a model that was fitted with a quadratic polynomial, i.e., \(\delta = p_{1} SR^{2} + p_{2} SR + p_{3}\). Their study demonstrated that fitting accuracy was high with relatively high surface roughness, but deteriorated with surface roughness lower than 6 μm. In addition, the constants in the model were determined by the process parameters, especially grinding speed and the vibration frequency of the grinding wheel. Consequently, the model should be calibrated for different process parameters, which obstructs its practical applications.

Wang et al. [7] correlated SSD depth with cutting force in the rotary ultrasonic face milling of a K9 glass. They found that SSD depth was proportional to the exponent of cutting force, i.e., \(\delta { = }\gamma F_{c}^{\chi }\). Due to the simplifications in deriving the model, the model may not be applicable to other materials and processes.

Although it is simple and easy to predict SSD depth by the predictive methods, the largest SSD depth, which is the most detrimental to the performance and the lifetime of a part, cannot precisely be predicted. Besides, because the prediction results mainly rely on surface roughness, subsurface cracks may propagate to a large depth beneath a relatively smooth surface [63]. Lakhdari et al. [30] found that SSD depth induced in ultrasonically assisted grinding was 35% less than the conventional grinding, even the surface quality is worse.

It should also be noted that many prediction models revealing the relationship between SSD and surface roughness were based on the quasi-static indentation fracture model proposed by Lawn et al. [64]. However, the situation in the practical processes is different from the indentation. High cutting speeds are often used in the practical machining processes, which leads to a high strain rate and may also cause high temperature in a machining area. The effects of temperature and strain rate on the material responses in machining should be considered in the predictive modeling of SSD.

4.2 Optical Coherent Tomography

The optical coherent tomography (OCT) is a new imaging detection technology. It was first applied to biology and medical diagnosis [65, 66]. The principle of OCT is based on the Michelson interferometry, as described in Figure 5. A light beam is emitted from a light source, then split into two beams by a beam splitter, one to the detection arm and the other to the reference arm. The light beam to the reference arm is reflected by a mirror, while the light beam to the detection arm irradiates the sample and is then reflected back. By moving the reference mirror, the two reflected light beams interfere with each other with the interference signal acquired by a detector. The signal is demodulated to receive the envelope function of the signal. The maximum of the interference function corresponds to the position of the mirror, which is used to infer the information on the sample.

Schematic diagram of optical coherent tomography [57]

The resolution of OCT depends on the coherent length of light L c , given in Eq. (8),

where c and λ0 are the propagation speed and the wavelength of the light, respectively; Δλ is the full-width of the coherence function at half-maximum measured in wavelength units; and ∆f is the spectral width of the source in the optical frequency domain. Because of the short coherence of the light, the interference between the detection and reference light beams takes place in the aplanatism condition at a longitude resolution of 10 μm.

Bashkansky et al. [67,68,69,70,71,72] used OCT to detect SSD depth up to 140 μm in ceramics and obtained the three-dimensional characteristics of SSD. However, the images were blur because of the strong surface scattering, weak subsurface scattering and big tomography interval. Sergeeva et al. [57] used the short coherent interferometry to measure the artificial SSD in a glass, and reported that the depth and lateral resolution were 10 μm and 4 μm, respectively. While in a practical situation, cracks show more complex configurations, such as “chevron”, “branch” and “fork” [73]. Some cracks are parallel to the surface, while others initiate at the middle of the existing cracks, with their propagation directions changing all the time.

Applicable to the materials that have strong light scattering property, OCT is usually used in the biology and medical diagnosis fields. For the semiconductor and optical materials, light scattered from SSD is too weak to have interference [74]. In addition, noises induced from surface scattering and reflection obstruct the processing of the targeted signals.

4.3 Laser Scattering

Various technologies have been proposed to detect SSD with laser scattering. Temple et al. [75, 76] used the total internal reflection microscopy (TIRM) to detect surface/subsurface damage of the transparent samples, and several other researchers applied TIRM to optical materials later [77,78,79,80,81]. Shown in Figure 6, a sample is put on a prism, with a layer of the matching fluid in between. Linearly polarized light passes through the prism and the matching fluid, and irradiates the sample. If the sample is damage-free, the total reflection takes place on the interface between the sample and air. Otherwise, the incident light is scattered by the damage within the sample. A portion of the scattered light passes through the sample to facilitate observations of the damage with a microscope. TIRM requires the sample with a low surface roughness and transparency to the incident light [40]. Additionally, TIRM is not suitable for quantitative measurements since it only provides qualitative results of SSD in a sample.

Schematic diagram of total internal reflection microscopy [75]

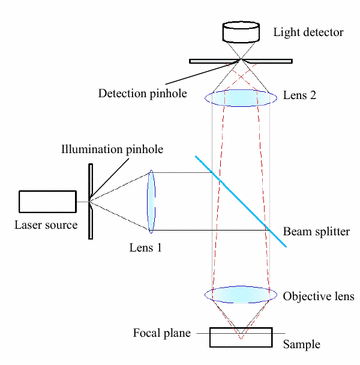

Confocal microscopy is also used recently for SSD detection. A schematic arrangement of the confocal microscopy is shown in Figure 7, in which light goes through an illumination pinhole, is reflected by a beam splitter, and is then focused by an objective lens on the sample. Light scattered from the sample is received by a light detector behind a detection pinhole (aperture) at the focal point of lens 2. The light offset from the focus is shut off by the detection pinhole plate. Therefore, only the light reflected from the focal point in the sample goes through the detection pinhole and is then received. The confocal microscopy provides higher resolution detection compared to the traditional microscopy, and has been applied to detecting SSD in ceramics [15, 82], optical parts [83] and semiconductor materials [5].

Schematic arrangement of confocal microscopy [83]

Winn et al. [82] used the confocal laser scanning microscopy (CLSM) to measure SSD in alumina. However, the maximum depth of measurement was limited within 20 μm in their study. Fine et al. [65] detected SSD in the polished and fine ground optical glass samples by CLSM with the resolution of 150 nm. Bertussi et al. [83] observed SSD in the fused silica optical components with the resolutions of 1 μm in depth and 0.26 μm in the scanning plane also by CLSM. Wang et al. [84] studied SSD by CLSM using a lens of a large numerical aperture and obtained the horizontal resolution of approximately 0.13 μm. However, CLSM requires that the samples under detection be with low surface roughness. Generally, CLSM is used for detection of a smooth surface as the light scattered from a rough surface interferes with the measurement.

The Argonne National Laboratory and the Kansas State University jointly developed the cross-polarization confocal microscopy (CPCM) to measure SSD in the ground ceramics and silicon wafers [5, 15, 85,86,87,88,89,90,91,92]. As shown in Figure 8, an incident light is linearly polarized and hits the surface of a sample. A portion of the light is reflected and scattered on the surface of the sample, while the other portion of the light penetrates into the sample. The surface scattering or reflecting light has the same polarization direction as the incident light, but the polarization direction of the transmission light is changed after being scattered by SSD, such as cracks and pores. The subsurface scattering light then refracts back to the air and combines with the surface scattering light, and is then filtered from the mixed lights with a polarized optical lens. The filtered light reflecting SSD is collected by a confocal microscopy system.

Schematic diagram of reflection, scattering and transmission of light on the surface of a sample [89]

The measurement system developed by Sun et al. [87] provides resolution higher than 1 μm in depth and enables to estimate the depth and extent of SSD in the sample of a rough surface. However, the system is limited in the lateral resolution. In a confocal microscopy, the system resolution is mainly depended on the diameter of the detection pinhole. The diameter of the pinhole is difficult to determine since it should match the wavelength of the incident light. In addition, the aberrations of the optical components and the errors in the adjustment of the light path should be also considered [74]. On the other hand, the refraction coefficient of the damage layer may be different from that of the damage-free matrix in a sample, and may vary along the depth because of the variation of SSD density. The effects of the variation of the refraction coefficient on the direction of light propagation are neglected in the previous studies [88, 90, 92]. In addition, the mechanism of the light scattering from SSD remains unknown. There are two light scattering mechanisms when an incident light encounters a scatter or non-homogeneity, i.e., Rayleigh scattering and Mie scattering. Rayleigh scattering predominates the scattering from a scatter which is much smaller than the wavelength. For the scatter similar to or larger than the wavelength, Mie scattering predominates. Both the two scattering mechanisms are applicable to the scattering from a general spherical scatter [93], whereas subsurface cracks are generally with the length of tens of microns and the width smaller than one micron in complex shapes. To our knowledge, the mechanism of the scattering from SSD is not fully interpreted. Therefore, further study and development are necessary.

4.4 Scanning Acoustic Microscopy

The scanning acoustic microscopy (SAM), as one of the ultrasonic detection methods, is a widely-used nondestructive technique for interior defect detection. A schematic of SAM is shown in Figure 9, in which an electrical radio frequency (RF) signal is sent to a piezoelectric transducer to transform into ultrasonic waves on the top surface of a sapphire delay rod. The waves propagate along the rod and are then focused into a sample through a coupling liquid with the concave end of the rod. While some waves reflect on the surface, the remaining waves penetrate into the sample and are scattered by the damage in the sample. The surface waves together with the subsurface scattering waves and noises are simultaneously received by a detector. The useful signals can be extracted from the received wave signals.

Schematic arrangement of scanning acoustic microscopy [97]

SAM has many advantages for the SSD detection. Both surface and subsurface defects can be detected at a high efficiency. However, SAM provides lateral resolution in the order of tens of microns [94,95,96,97,98], which is not applicable to the ultra-precision manufacturing. Generally, the signal acquired by SAM is combined with strong spurious signals which come from the surface waves and elastic waves in acoustic elements [96], making it difficult to distinguish the SSD information. In addition, SAM is normally applied to detecting the sample of a smooth surface. It may be difficult to apply to a sample with a rough surface due to the influence of the surface scattering waves.

The non-destructive methods preserve samples and save sample preparing time, which is in favor of improving overall manufacturing efficiency and reducing cost. However, there are still some limitations to overcome in the future. The methods are listed and compared in Table 2.

5 Other Methods

Neauport et al. [35] added a little amount of barium into slurry during grinding, tracked the barium at different etching depths with the inductively coupled plasma-atomic emission spectrometry (ICP-AES), and inferred the depth of subsurface cracks. Similarly, “quantum dots” were used during lapping to detect the subsurface cracks [99, 100]. The quantum dots were fluorescent particles of the nanometer-size. The method was to reveal the depth of subsurface cracks by detecting the intensity of the fluorescence emitted from the quantum dots trapped in the subsurface cracks. However, since the width of a subsurface crack is normally less than one micron, the slurry is prevented from wetting the tip of the crack because of the surface tension of the slurry. Therefore, the measurement result of SSD is typically smaller than the real depth of the subsurface crack, which is also a problem with the dye penetration method [13, 101].

Podymova et al. [102, 103] measured the thickness of damage layer in the mono-crystalline silicon wafer with the laser optoacoustic method. The method was based on different mechanisms of laser-excited ultrasonic in the damaged layer and damage-free matrix, i.e., concentration-deformation mechanism in the matrix and thermal elastic deformation in the damaged layer. The thickness of the damaged layer could be inferred through the received ultrasonic signal with the method. However, the method is limited in detection depth to less than 10 μm and inapplicable to detecting the spatial distribution of SSD.

The X-ray diffraction (XRD) method is used to measure the machining-induced stress in the semiconductor materials [23, 85]. Generally, the diffraction spectrum is narrow and sharp if a sample does not have residual stresses; otherwise, the spectrum is broadened with diffraction peaks shifted. Residual stresses are determined based on a comparison between the measured and the standard diffraction spectra. However, since the X-ray penetration depth is limited in the most-used materials, XRD is only applicable to detecting the surface residual stresses.

The X-ray computed tomography (CT) is a powerful technique in revealing the three-dimensional microstructures of SSD. This technique is to take a number of 2D radiographic projections and then to reconstruct a 3D model without destroying a sample. The laboratory micro-focus computed tomography (micro CT), the synchrotron radiation computed tomography (SRCT), and the synchrotron radiation computed laminography (SRCL) are also utilized to detect micro defects with a high resolution of a few microns or higher [104,105,106]. The major drawback of CT is the radiation of X-ray which may hazard operator health.

The micro-Raman spectroscopy is usually used to measure residual stresses and phase transformation [107,108,109]. In this technique, light radiates a sample surface and is then scattered by the surface. Most of the incident light is elastically scattered, which means the scattered light has the same frequency as the incident light. However, the remaining of the incident light is non-elastically scattered, which means the scattered light has a different frequency than the incident light. This phenomenon is the inherent property of a material. Based on a Raman spectrum, residual strain, impurities, lattice distortion, and phase transformation of a sample can thus be estimated. Frequency shifts of a Raman spectrum indicates the information of the residual stresses and the phase transformation in the sample. This technique is simple and precise, but cannot detect subsurface cracks. Additionally, the technique is usually to detect a sample point-by-point rather than to scan the surface of the sample, which is time-consuming and less efficient.

Eddy current detection (ECD) is an efficient non-destructive method for detection of surface and subsurface defects in conductive materials. Eddy currents are loops of electrical current induced by an alternating magnetic field in a conductor due to Faraday’s law of induction. In ECD, an ECD probe applies an excitation magnetic field to a part being detected to induce eddy currents in the part. The eddy currents create a magnetic field that reacts back on the excitation field, which results in a change in the impedance of the probe. Thus, a surface or subsurface defect can be detected based on the change in the impedance. ECD is widely applied to detecting subsurface defects [110] and residual stresses [111]. HE et al. proposed the induction thermography [112] and the eddy current pulse phase thermography [113] to detect SSD in steels and carbon fiber reinforced plastics. Practically, ECD has a limited application to the conductive and non-ferromagnetic materials, such as titanium alloys, aluminum alloys and carbon fiber reinforced composites.

For conductive ferromagnetic materials, such as maraging steels, the magnetic Barkhausen noise (MBN) detection technique can be used to evaluate residual stresses [114], impurities [115] and phase transformation [116] in the surface or subsurface of a part. An MBN signal represents discontinuous changes in the magnetization within a ferromagnetic material resulting from the change in an external magnetic field. The ECD and MBN techniques can only be applied to conductive and ferromagnetic materials, respectively. However, they are not suitable for non- or semi-conductive materials, such as ceramics, glass or silicon wafers.

6 Discussion

Different hard and brittle materials have different properties that can result in different responses to a machining process. If the response of a material is known, it becomes possible to control the process so as to obtain the desirable surface integrity of the part made of the material. The response could be indicated by the spatial run and the distribution of the cracks in the machined part. In the process, the spatial run and the distribution of the induced subsurface cracks are influenced by many factors, including direction, magnitude and rate of the acting force and the anisotropy of the workpiece material. For example, in a monocrystalline silicon wafer, cracks initiate more easily in the {111} planes than other planes in the process since the {111} planes are the cleavage planes. The planes in which the cracks initiate are generally incline to the machined surface [2]. The crack behavior is complex and a propagating crack may branch into multiple cracks [117,118,119,120]. Consequently, SSD presents complex configurations in the machined workpiece [73].

In a destructive method, only the SSD in the prepared section can be measured. The way to access the spatial run and the distribution is to prepare a set of sections, obtain the SSD in each section, and then reconstruct the spatial configurations. The predictive methods ignore the effect of the crystallographic orientation of a crystal on crack propagation in machining and consider that SSD and surface roughness are determined by median cracks and lateral cracks, respectively.

Tool wear is common in machining hard and brittle materials and significantly influences the SSD in a part [121,122,123]. In grinding, the SSD induced in machining generally increases with tool wear. It is unreasonable to choose the same parameters for subsequent processes due to the increased SSD from the previous process. Consequently, in-process detection provides real-time SSD information and helps optimize the subsequent processes. The destructive methods are difficult to integrate into a production line, while the non-destructive methods could achieve the in-process monitoring [40].

7 Summaries and Outlook

Hard and brittle materials are hard to machine since SSD is easily induced in a machining process. Detecting SSD is a key link in an overall manufacturing chain, while the aforementioned methods applied to detecting SSD have associated limitations with respect to system resolution, detection depth and efficiency, as well as material type.

In this paper, the methods for detection of SSD in hard and brittle materials are reviewed. The destructive methods can provide observable, reliable, and quantitative information but are inapplicable to estimating the global information of SSD in a sample. Besides, the sample has to be destroyed, which is costly and time-consuming. The detection cost is acceptable in the mass production and non-flexible manufacturing processes. Otherwise, the non-destructive methods are more applicable and efficient. In the future, customized parts become more popular, which demands non-destructive methods for rapid estimation of the SSD induced in a part. In addition, the non-destructive methods are easier to integrate into a production line. It is anticipated that nondestructive methods are developed to meet the ever increasing demand on high quality manufacturing of the industrial parts made of hard and brittle materials.

References

S Gao. Fundamental research on silicon wafer thinning by ultra-precision grinding. Dalian University of Technology, 2013. (in Chinese)

Y X Zhang. Study on the surface layer damage of monocyrstalline silicon wafer induced by ultra-precision grinding. Dalian University of Technology, 2006. (in Chinese)

Z J Pei. A study on surface grinding of 300 mm silicon wafers. International Journal of Machine Tools and Manufacture, 2002, 42(3): 385–393.

R K Kang, Y X Zhang, D M Guo, et al. Study on the Surface and Subsurface Integrity of Ground Monocrystalline Silicon Wafers. Key Engineering Materials, 2005, 291–292: 425–432.

J M Zhang, J G Sun, Z J Pei. Application of Laser scattering on detection of subsurface damage in silicon wafers. ASME 2003 International Mechanical Engineering Congress and Exposition, Washington, DC, USA, November 15–21, 2003: 15–24.

H N Li, T B Yu, L D Zhu, et al. Evaluation of grinding-induced subsurface damage in optical glass BK7. Journal of Materials Processing Technology, 2016, 229: 785–794.

J J Wang, C L Zhang, P F Feng, et al. A model for prediction of subsurface damage in rotary ultrasonic face milling of optical K9 glass. The International Journal of Advanced Manufacturing Technology, 2016, 83(1–4): 347–355.

J B Chen, Q H Fang, P Li. Effect of grinding wheel spindle vibration on surface roughness and subsurface damage in brittle material grinding. International Journal of Machine Tools and Manufacture, 2015, 91: 12–23.

D X Lv, Y H Huang, Y J Tang, et al. Relationship between subsurface damage and surface roughness of glass BK7 in rotary ultrasonic machining and conventional grinding processes. The International Journal of Advanced Manufacturing Technology, 2013, 67(1–4): 613–622.

Z Q Yao, W B Gu, K M Li. Relationship between surface roughness and subsurface crack depth during grinding of optical glass BK7. Journal of Materials Processing Technology, 2012, 212(4): 969–976.

S Y Li, Z Wang, Y L Wu. Relationship between subsurface damage and surface roughness of optical materials in grinding and lapping processes. Journal of Materials Processing Technology, 2008, 205(1–3): 34–41.

J Neauport, C Ambard, H Bercegol, et al. Optimizing fused silica polishing processes for 351nm high-power laser application. Proceedings of SPIE-The International Society for Optical Engineering, 2008, 7132: 51.

W Kanematsu. Visualization of subsurface damage in silicon nitride from grinding by a plasma etching and dye impregnation method. Journal of the American Ceramic Society, 2006, 89(8): 2564–2570.

B Zhang, T Histoshi, Y Masanori. Study on surface cracking of alumina scratched by single-point diamonds. Journal of Materials Science, 1988, 23(9): 3214–3224.

J G Sun, M Shirber, W A Ellingson. Laser-based optical scattering detection of surface and subsurface defects in machined Si3N4 components. John Wiley & Sons, Inc., 1997: 273–280.

N Azeggagh, L Joly-Pottuz, D Nélias, et al. Hertzian contact damage in silicon nitride ceramics with different porosity contents. Journal of the European Ceramic Society, 2015, 35(8): 2269–2276.

B Zhang, T D Howes. Subsurface evaluation of ground ceramics. CIRP Annals—Manufacturing Technology, 1995, 44(1): 263–266.

B Zhang, J Meng. Grinding damage in fine ceramics. Nanotechnology & Precision Engineering, 2003, 1(1): 48–56. (in Chinese)

Z Wang. Study on the detection and control techniques of subsurface damage in optical fabrication. National University of Defense Technology, 2008. (in Chinese)

H K Tonshoff, B Karpuschewski, M Hartmann, et al. Grinding-and-slicing technique as an advanced technology for silicon wafer slicing. Machining Science and Technology, 1997, 1(1): 33–47.

B Zhang, T D Howes. Material-removal mechanisms in grinding ceramics. CIRP Annals—Manufacturing Technology, 1994, 43(1): 305–308.

P P Hed, D F Edwards, J B Davis. Subsurface damage in optical materials: Origin, measurement and removal: Summary. Lawrence Livermore National Lab., CA (USA), 1988.

H K Tönshoff, W V Schmieden, I Inasaki, et al. Abrasive machining of silicon. CIRP Annals-Manufacturing Technology, 1990, 39(2): 621–635.

X Tonnellier, P Shore, X Luo, et al. Wheel wear and surface/subsurface qualities when precision grinding optical materials. Proc. SPIE, 2006, 6273: 627308.

F W Huo. Study on the mechanism of ductile mode grinding of silicon wafers. Dalian University of Technology, 2006. (in Chinese)

Y X Zhang, D L Li, G Wei, et al. Experimental investigation on the detection technique for surface layer damage of machined silicon wafers. Rengong Jingti Xuebao/Journal of Synthetic Crystals, 2011, 40(2): 359–364.

Y Masanori, B Zhang, T Hitoshi. Observations of ceramic surface cracks by newly proposed methods. Yogyo-Kyokai-Shi, 1987, 95(10): 961–969. (in Japanese)

S D Jacobs, J C Lambropoulos, D Golini, et al. Use of magnetorheological finishing (MRF) to relieve residual stress and subsurface damage on lapped semiconductor silicon wafers. Proceedings of SPIE-The International Society for Optical Engineering, 2001, 4451: 286–294.

Y Y Zhou, P D Funkenbusch, D J Quesnel, et al. Effect of etching and imaging mode on the measurement of subsurface damage in microground optical-glasses. Journal of the American Ceramic Society, 1994, 77(12): 3277–3280.

F Lakhdari, D Bouzid, N Belkhir, et al. Surface and subsurface damage in Zerodur® glass ceramic during ultrasonic assisted grinding. The International Journal of Advanced Manufacturing Technology, 2017, 90(5–8): 1993–2000.

J A Randi, J C Lambropoulos, S D Jacobs. Subsurface damage in some single crystalline optical materials. Appl. Opt., 2005, 44(12): 2241–2249.

T Suratwala, L Wong, P Miller, et al. Sub-surface mechanical damage distributions during grinding of fused silica. Journal of Non-Crystalline Solids, 2006, 352(52–54): 5601–5617.

P E Miller, T I Suratwala, L L Wong, et al. The distribution of subsurface damage in fused silica. Proceedings of SPIE-The International Society for Optical Engineering, 2005: 599101–599101–25.

J A Menapace, P J Davis, W A Steele, et al. MRF applications: measurement of process-dependent subsurface damage in optical materials using the MRF wedge technique. Proceedings of SPIE-The International Society for Optical Engineering, 2005: 599103–599103–11.

J Neauport, C Ambard, P Cormont, et al. Subsurface damage measurement of ground fused silica parts by HF etching techniques. Opt. Express, 2009, 17(22): 20448–20456.

A B Shorey, S D Jacobs, W I Kordonski, et al. Experiments and observations regarding the mechanisms of glass removal in magnetorheological finishing. Appl. Opt., 2001, 40(1): 20–33.

A B Shorey. Mechanisms of material removal in magnetorheological finishing (MRF) of glass. University of Rochester, 2000.

C Miao, S N Shafrir, J C Lambropoulos, et al. Shear stress in magnetorheological finishing for glasses. Appl. Opt., 2009, 48(13): 2585–2594.

T O Mulhearn. The deformation of metals by Vickers-type pyramidal indenters. Journal of the Mechanics and Physics of Solids, 1959, 7(2): 85–88.

J Wang, Y G Li, J H Han, et al. Evaluating subsurface damage in optical glasses. Journal of the European Optical Society-Rapid Publications, 2011, 6(11001).

S Van der Zwaag, J T Hagan, J E Field. Studies of contact damage in polycrystalline zinc sulphide. Journal of Materials Science, 1980, 15(12): 2965–2972.

H H Xu, S Jahanmir. Simple technique for observing subsurface damage in machining of ceramics. Journal of the American Ceramic Society, 1994, 77(5): 1388–1390.

F Guiberteau, N P Padture, B R Lawn. Effect of grain size on Hertzian contact damage in alumina. Journal of the American Ceramic Society, 1994, 77(7): 1825–1831.

D S Anderson, M E Frogner. A method for the evaluation of subsurface damage. Technical Digest of the Optical Fabrication and Testing Workshop. Optical Society of America, Washington DC, USA, 1985.

H Helbawi, L C Zhang, I Zarudi. Difference in subsurface damage in indented specimens with and without bonding layer. International Journal of Mechanical Sciences, 2001, 43(4): 1107–1121.

C W Carr, M J Matthews, J D Bude, et al. The effect of laser pulse duration on laser-induced damage in KDP and SiO2. Proc. SPIE, 2006: 6403.

I Zarudi, L Zhang. Subsurface damage in single-crystal silicon due to grinding and polishing. Journal of Materials Science Letters, 1996, 15(7): 586–587.

T Abe, Y Nakazato, M Daito, et al. The ductile mode grinding technology applied to silicon wafering process. Semiconductor Silicon/1994, Proceedings of the 7th International Symposium on Silicon Materials Science and Technology, The Electrochemical Society, Pennington, NJ, USA, 1994: 207–217.

H Z Wu, S G Roberts, G Möbus, et al. Subsurface damage analysis by TEM and 3D FIB crack mapping in alumina and alumina/5vol.%SiC nanocomposites. Acta Materialia, 2003, 51(1): 149–163.

L Wong, T Suratwala, M D Feit, et al. The effect of HF/NH4F etching on the morphology of surface fractures on fused silica. Journal of Non-Crystalline Solids, 2009, 355(13): 797–810.

B Ma, Z X Shen, Z Zhang, et al. Fabrication and detection technique of fused silica substrate with extremely low subsurface damage. High Power Laser & Particle Beams, 2010, 22(9): 2181–2185.

G Spierings. Wet chemical etching of silicate-glasses in hydrofluoric-acid based solutions. Journal of Materials Science, 1993, 28(23): 6261–6273.

G L Li. Theoretical and experimental research on the measurement of grinding subsurface damage for optical materials. National University of Defense Technology, 2006. (in Chinese)

Z Wang, Y L Wu, Y F Dai, et al. Rapid detection of subsurface damage of optical materials in lapping process and its influence regularity. Guangxue Jingmi Gongcheng/Optics & Precision Engineering, 2008, 16(1): 16–21.

R Sabia, H J Stevens, J R Varner. Pitting of a glass-ceramic during polishing with cerium oxide. Journal of Non-Crystalline Solids, 1999, 249(2–3): 123–130.

B Ma, Z X Shen, P F He, et al. Detection of subsurface defects of fused silica optics by confocal scattering microscopy. Chinese Optics Letters, 2010, 8(3): 296–299.

M Sergeeva, K Khrenikov, T Hellmuth, et al. Sub surface damage measurements based on short coherent interferometry. Journal of the European Optical Society-Rapid Publications, 2010, 5: 10003–1-5.

P P Hed, D F Edwards. Optical glass fabrication technology. 2: Relationship between surface roughness and subsurface damage. Appl. Opt., 1987, 26(21): 4677–4680.

J C Lambropoulos. From abrasive size to subsurface damage in grinding. Convergence, 2000, 8: 1–3.

F K Aleinikov. The effect of certain physical and mechanical properties on the grinding of brittle materials. Soviet Physics-Technical Physics, 1957, 2(12): 2529–2538.

J C Lambropoulos, Y Li, P D Funkenbusch, et al. Noncontact estimate of grinding-induced subsurface damage. SPIE’s International Symposium on Optical Science, Engineering, and Instrumentation. International Society for Optics and Photonics, 1999: 41–50

J Neauport, J Destribats, C Maunier, et al. Loose abrasive slurries for optical glass lapping. Appl. Opt., 2010, 49(30): 5736–5745.

K R Fine, R Garbe, T Gip, et al. Non-destructive real-time direct measurement of subsurface damage. Defense and Security. International Society for Optics and Photonics, Orlando, Florida, USA, March 28, 2005: 105–110.

B Lawn, R Wilshaw. Indentation fracture: principles and applications. Journal of Materials Science, 1975, 10(6): 1049–1081.

D Huang, E A Swanson, C P Lin, et al. Optical coherence tomography. Science, 1991, 254(5035): 1178–1181.

V V Tuchin, R K Wang, V V Tuchin. Optical coherence tomography: light scattering and imaging enhancement. In: Handbook of coherent-domain optical methods, Springer New York, 2013: 665–742.

M Bashkansky, M D Duncan, M Kahn, et al. Subsurface defect detection in ceramics by high-speed high-resolution optical coherent tomography. Optics Letters, 1997, 22(1): 61–63.

M Bashkansky, P R Battle, M Duncan, et al. Subsurface defect detection in ceramic materials using optical gating techniques. Review of Progress in Quantitative Nondestructive Evaluation, Springer, 1996: 1565–1572.

D O Thompson, D E Chimenti, M Bashkansky, et al. Subsurface defect detection in ceramic materials using optical gating techniques. Review of Progress in Quantitative Nondestructive Evaluation. Springer US, 1996: 1565–1572.

P R Battle, M Bashkansky, R Mahon, et al. Subsurface defect detection in ceramic materials using optical gating techniques. Optical Engineering, 1996, 35(4): 1119–1123.

M Bashkansky, P R Battle, M D Duncan, et al. Subsurface defect detection in ceramics using an optical gated scatter reflectometer. Journal of the American Ceramic Society, 1996, 79(5): 1397–1400.

M Duncan, M Bashkansky, J Reintjes. Subsurface defect detection in materials using optical coherence tomography. Opt. Express, 1998, 2(13): 540–545.

Z J Pei, S R Billingsley, S Miura. Grinding induced subsurface cracks in silicon wafers. International Journal of Machine Tools and Manufacture, 1999, 39(7): 1103–1116.

C H Wang. Study on optical sub-surface damage evaluation technology. Xi’an: Xi’an Technological University, 2010. (in Chinese)

P A Temple. Total internal reflection microscopy: a surface inspection technique. Appl. Opt., 1981, 20(15): 2656–2664.

P A Temple. Examination of laser damage sites of transparent surfaces and films using total internal reflection microscopy. Natl. Bur. Std. Spec. Publ. 1980, 568: 333–341.

F Draheim, B Harnisch, T Weigel. Subsurface damage of optical components and the influence on scattering properties. Proceedings of SPIE-The International Society for Optical Engineering, 1994: 709–720.

C F Kranenberg, K C Jungling. Subsurface damage identification in optically transparent materials using a nondestructive method. Appl. Opt., 1994, 33(19): 4248–4253.

Z M Liao, S J Cohen, J R Taylor. Total internal reflection microscopy (TIRM) as a nondestructive subsurface damage assessment tool. Proc. SPIE, 1994: 43–53.

L M Sheehan, M Kozlowski, D W Camp. Application of total internal reflection microscopy for laser damage studies on fused silica. Proceedings of SPIE-The International Society for Optical Engineering, 1998, 3244(6): 282–295.

Y Deng, Q Xu, L Q Chai, et al. Total internal reflection microscopy: A subsurface defects identification technique in optically transparent components. High Power Laser & Particle Beams, 2009, 21(6): 835–840.

A J Winn, J A Yeomans. A study of microhardness indentation fracture in alumina using confocal scanning laser microscopy. Philosophical Magazine A-Physics of Condensed Matter Structure Defects and Mechanical Properties, 1996, 74(5): 1253–1263.

B Bertussi, P Cormont, S Palmier, et al. Initiation of laser-induced damage sites in fused silica optical components. Opt. Express, 2009, 17(14): 11469–11479.

C H Wang. Optical subsurface damage evaluation using LSCT. Proc. SPIE, 2009, 7522: 75226K–75226K-7.

W K Lu, Z J Pei, J G Sun. Non-destructive evaluation methods for subsurface damage in silicon wafers: A literature review. International Journal of Machining and Machinability of Materials, 2007, 2(1): 125–142.

W K Lu, J G Sun, Z J. Pei Subsurface damage measurement in silicon wafers with cross-polarisation confocal microscopy. International Journal of Nanomanufacturing, 2006, 1(2): 272–282.

J Sun. Device and nondestructive method to determine subsurface micro-structure in dense materials. Argonne National Laboratory (ANL), Argonne, IL, 2006.

J M Zhang, J G Sun, Z J Pei. Subsurface damage measurement in silicon wafers by laser scattering. Trans. NAMRI/SME, 2002, 30: 535–542.

J G Sun, A Wolosewicz, M H Haselkorn, et al. Laser scattering detection and characterization of defects and machining damage in silicon nitride components. Office of Scientific & Technical Information Technical Reports, 1998.

J M Zhang, J G Sun. Quantitative assessment of subsurface damage depth in silicon wafers based on optical transmission properties. International Journal of Manufacturing Technology and Management, 2005, 7(5–6): 540–552.

J M Zhang, J G Sun, Z J Pei. Optical transmission properties of silicon wafers: theoretical analysis. ASME 2004 International Mechanical Engineering Congress and Exposition. American Society of Mechanical Engineers, Anaheim, California, USA, November 13–19, 2004: 17–24.

J M Zhang. Laser scattering techniques for subsurface damage measurements: system development, experimental investigation, and theoretical analysis. Kansas State University, 2006.

D W Hahn. Light scattering theory. Department of Mechanical and Aerospace Engineering, Florida, 2006.

A Y Sun, B F Ju. The acoustic micro integrated detection technique for silicon wafer processing. Advanced Materials Research, 2012, 497: 151–155.

O Balogun, G D Cole, R Huber, et al. High-spatial-resolution sub-surface imaging using a laser-based acoustic microscopy technique. IEEE Transactions on Ultrasonics, Ferroelectrics and Frequency Control, 2011, 58(1): 226–233.

Y V Korkh, A M Burkhanov, A B Rinkevich. Scanning acoustic microscope for visualization of microflaws in solids. Russian Journal of Nondestructive Testing, 2009, 45(10): 677–684.

C T Leondes, J Janting. Techniques in scanning acoustic microscopy for enhanced failure and material analysis of microsystems. Leondes C T, Springer US, 2006: 905–921.

D Rats, J V Stebut, F Augereau. High frequency scanning acoustic microscopy: a novel non-destructive surface analytical tool for assessment of coating-specific elastic moduli and tomographic study of subsurface defects. Thin Solid Films, 1999, s355–356(2): 347–352.

W Williams, B Mullany, W Parker, et al. Using quantum dots to evaluate subsurface damage depths and formation mechanisms in glass. CIRP Annals-Manufacturing Technology, 2010, 59(1): 569–572.

W B Williams, B A Mullany, W C Parker, et al. Using quantum dots to tag subsurface damage in lapped and polished glass samples. Applied Optics, 2009, 48(27): 5155–5163.

T Yonushonis. Manufacturing fluid including fluorescent dye penetrant and method for using to make components: U.S. Patent 6,677,584. 2004-1-13.

N Podymova, A Karabutov. Laser optoacoustic non-destructive method of thickness measurement of subsurface damaged layer in machined silicon wafers. Journal of Physics: Conference Series. IOP Publishing, 2010, 214(1): 012054.

A A KARABUTOV, N B PODYMOVA. Study on the subsurface damage depth in machined silicon wafers by the laser-ultrasonic method. Case Studies in Nondestructive Testing and Evaluation, 2014, 1: 7–12.

L Lavery, W Harris, J Gelb, et al. Recent advancements in 3D X-ray microscopes for additive manufacturing. Microscopy and Microanalysis, 2015, 21(S3): 131–132.

D J Bull, L Helfen, I Sinclair, et al. A comparison of multi-scale 3D X-ray tomographic inspection techniques for assessing carbon fibre composite impact damage. Composites Science and Technology, 2013, 75: 55–61.

J Lambert, A R Chambers, I Sinclair, et al. 3D damage characterisation and the role of voids in the fatigue of wind turbine blade materials. Composites Science and Technology, 2012, 72(2): 337–343.

S Dutta, G Saxena, K Jindal, et al. Comparison of residual stress in deep boron diffused silicon (100), (110) and (111) wafers. Materials Letters, 2013, 100: 44–46.

J W Yan. Laser micro-Raman spectroscopy of single-point diamond machined silicon substrates. Journal of Applied Physics, 2004, 95(4): 2094–2101.

D W Ingrid. Raman spectroscopy: Chips and stress. Spectroscopy Europe, 2003, 15(2): 6–13.

W Du, Q Bai, Y B Wang, et al. Eddy current detection of subsurface defects for additive/subtractive hybrid manufacturing. The International Journal of Advanced Manufacturing Technology, 2017: 1–11.

M Morozov, G Y Tian, P J Withers. Noncontact evaluation of the dependency of electrical conductivity on stress for various Al alloys as a function of plastic deformation and annealing. Journal of Applied Physics, 2010, 108(2): 024909.

Y He, M Pan, F Luo. Defect characterization based on heat diffusion using induction thermography testing. Review of Scientific Instruments, 2012, 83(10): 104702.

Y He, M Pan, G Y Tian, et al. Eddy current pulsed phase thermography for subsurface defect quantitatively evaluation. Applied Physics Letters, 2013, 103(14): 144108.

P Vourna, A Ktena, P E Tsakiridis, et al. An accurate evaluation of the residual stress of welded electrical steels with magnetic Barkhausen noise. Measurement, 2015, 71: 31–45.

J A Perez-Benitez, J Capo-Sanchez, J Anglada-Rivera, et al. A study of plastic deformation around a defect using the magnetic Barkhausen noise in ASTM 36 steel. Ndt & e International, 2008, 41(1): 53–58.

A Stupakov, M Neslušan, O Perevertov. Detection of a milling-induced surface damage by the magnetic Barkhausen noise. Journal of Magnetism and Magnetic Materials, 2016, 410: 198–209.

K Ravi-Chandar, W G Knauss. An experimental investigation into dynamic fracture: I. Crack initiation and arrest. International Journal of Fracture, 1984, 25(4): 247–262.

K Ravi-Chandar, W G Knauss. An experimental investigation into dynamic fracture: II. Microstructural aspects. International Journal of Fracture, 1984, 26(1): 65–80.

K Ravi-Chandar, W G Knauss. An experimental investigation into dynamic fracture: III. On steady-state crack propagation and crack branching. International Journal of fracture, 1984, 26(2): 141–154.

K Ravi-Chandar, W G Knauss. An experimental investigation into dynamic fracture: IV. On the interaction of stress waves with propagating cracks. International Journal of Fracture, 1984, 26(3): 189–200.

J Y Shen, J Q Wang, B Jiang, et al. Study on wear of diamond wheel in ultrasonic vibration-assisted grinding ceramic. Wear, 2015, 332: 788–793.

Q Zhang, S To, Q Zhao, et al. Impact of material microstructure and diamond grit wear on surface finish in micro-grinding of RB-SiC/Si and WC/Co carbides. International Journal of Refractory Metals and Hard Materials, 2015, 51: 258–263.

K Fathima, A S Kumar, M Rahman, et al. A study on wear mechanism and wear reduction strategies in grinding wheels used for ELID grinding. Wear, 2003, 254(12): 1247–1255.

Authors’ Contributions

J-FY, QB and BZ were all in charge of the whole trial; J-FY wrote the manuscript; QB and BZ assisted with the revision. All authors have read and approved the final manuscript.

Authors’ Information

Jing-Fei Yin, is currently a PhD candidate at Key Laboratory for Precision and Non-traditional Machining Technology of Ministry of Education, Dalian University of Technology, China. E-mail: 2296302449@qq.com.

Qian Bai, is currently an associate professor at School of Mechanical Engineering, Dalian University of Technology, China. E-mail: baiqian@dlut.edu.cn.

Bi Zhang, is currently a professor at Department of Mechanical Engineering, University of Connecticut, USA. E-mail: 15140572053@qq.com.

Competing Interests

The authors declare that they have no competing interests.

Ethics Approval and Consent to Participate

Not applicable.

Funding

Supported by National Natural Science Foundation of China (Grant No. 51575084), the Science Fund for Creative Research Groups of NSFC (Grant No. 51621064) and the Science Challenge Project (Grant No. JCKY2016212A506–0101).

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Yin, Jf., Bai, Q. & Zhang, B. Methods for Detection of Subsurface Damage: A Review. Chin. J. Mech. Eng. 31, 41 (2018). https://doi.org/10.1186/s10033-018-0229-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s10033-018-0229-2